Recovery of Critical Minerals from Coal Mine Waste and Coal Ash

Background and Context

-

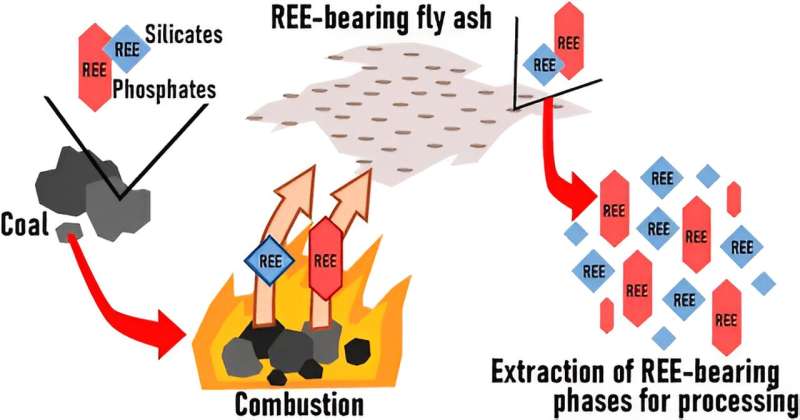

India is exploring coal waste and ash as alternative sources for Critical Minerals, especially Rare Earth Elements (REE).

-

Fly ash, bottom ash, and overburden from coal mining are found to contain significant concentrations of REE and Yttrium.

-

This initiative supports India’s broader self-reliance and clean energy goals, including the National Critical Minerals Mission (NCMM).

Key Findings from Recent Studies

a) Singareni Thermal Power Plant (STPP)

-

Total REE in fly ash and overburden clay: ~400 ppm

b) NLC India Ltd., Neyveli (Tamil Nadu)

-

Fly ash REE concentration: 2100 mg/kg

-

Yttrium content: 300 mg/kg

-

Contains both Light REEs (LREE) and Heavy REEs (HREE)

c) Coal India Ltd. R&D Findings

-

North Eastern Region (NER) Coalfields:

-

Low total REE, but high HREE content

-

-

Gondwana Sediments (Singrauli coalfield):

-

REE enrichment:

-

Coal samples: ~250 ppm

-

Non-coal samples: ~400 ppm

-

-

Extraction viability depends on tech advancement and economic feasibility

-

-

North Eastern Coalfields:

-

Developing indigenous technology for extraction:

-

Enrichment via physical separation

-

Extraction via Ion-Exchange Resin and Acid Mine Drainage treatment

-

-

National Critical Mineral Mission (NCMM)

-

Launched: 29 January 2025

-

Duration: 2024–25 to 2030–31

-

Objective: Secure supply chain of Critical Minerals

-

Allocation: ₹100 crore for pilot projects (e.g., fly ash, overburden, red mud)

-

Centre of Excellence (CoE): Guidelines approved on 6 April 2025

Institutional Collaborations

-

SCCL signed MoUs with:

-

IMMT, Bhubaneswar

-

NFTDC, Hyderabad

-

IIT Hyderabad

-

Significance for UPSC

-

Supports energy security, Atmanirbhar Bharat, and critical mineral diplomacy

-

Aligns with India’s Clean Energy Transition and Rare Earth Security Strategy

-

Offers an eco-friendly solution by utilizing waste for wealth from coal mining